Learning from Air Accident Investigations

In 1989, a hidden engine defect doomed United Flight 232, killing 112. Decades later, Qantas Flight 32 suffered a similar failure but landed safely. Smarter systems and lessons learned turned potential tragedy into triumph. Two flights, one cause, two very different outcomes.

United Airlines Flight 232 crashed on the 19th of July 1989, killing 112 of the 296 people aboard the flight en route to Chicago from Denver.

The crash was caused by the fan disk of the rear engine suddenly failing at high speed. It split into three parts, two of which were recovered. Investigators determined which crack was the initial one by piecing together the remains of the disk and observing the cracks branching out from each other

When producing accident reports, it is necessary to determine why the initial crack occurred. A common reason for fan disk failure is ‘biological interference,’ such as a bird flying into the engine. Typical signs of this include reduced damage further into the engine. However, due to the extent of the crash damage, this was likely abandoned as a line of inquiry. Another sign of bird strikes is organic remains smeared over the fan disk. These remains are often not visible to the naked eye but become clear under UV light.

In the case of United Airlines Flight 232, it was concluded that the failure was not caused by a bird strike but rather by a defect in the metal itself

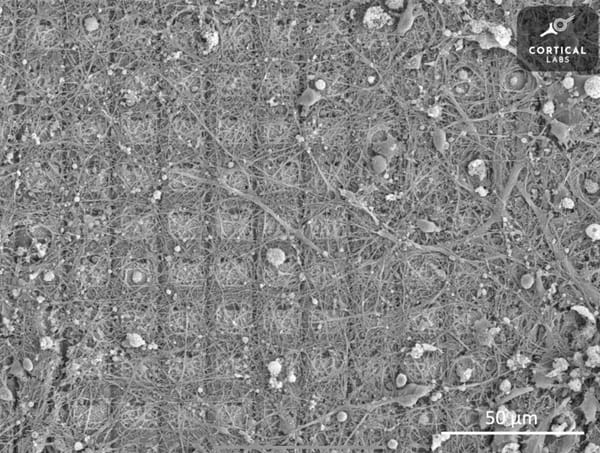

General Electric, the manufacturer of the engine used in this aircraft, would have sent the disk fragments to their laboratory for microscopic examination. It was discovered that the crack was caused by an oxidised piece of titanium (referred to as an alpha defect in the accident report). This defect is much more brittle than the titanium used for fan disks, resulting in a stress fracture developing over time. Initially, this fracture would have been small. The accident report concluded that there had been missed opportunities to detect the defect. Due to the high temperatures involved in manufacturing, this is a well-known potential issue. The metal is routinely examined for cracks, and alpha defects are usually detected using ultrasound inspection methods. For unknown reasons, presumably human error, this defect was overlooked during previous inspections and allowed to develop into a serious problem.

Although the report primarily attributes blame to the failure to detect the metallurgical defect, it also highlights that the lack of a failsafe in the hydraulic system once damaged at the rear of the plane (which ultimately forced the pilot to crash-land rather than divert to a nearby airport on the remaining two engines) contributed to the severity of the crash. Newer versions of the aircraft involved in this accident incorporated hydraulic fuses to isolate damaged areas, maintaining some control of the plane.

Qantas Flight 32 was a flight on the 4th of November 2010 that suffered a similar failure but landed safely with no fatalities. It experienced a similar issue—a failed engine whose debris damaged the hydraulic system—but it was caused by a different problem. A small oil pipe had been mistakenly manufactured too thinly. It eventually wore through, creating a surge of hot, pressurised oil and air, which reacted explosively. The metal connection between the turbine and the rest of the engine melted, causing the turbine to spin excessively and break apart. One of the broken pieces damaged the hydraulic system.

In the United Flight 232 accident, the engine mounted at the rear of the plane severely damaged the hydraulic system. However, in the Qantas incident more than two decades later, the aircraft had multiple hydraulic systems in different parts of the plane. This redundancy allowed some control surfaces to remain effective, with one engine operating normally. The additional control enabled the crew of the Qantas flight to circle while addressing the damage and then formulate a safe landing plan, returning to Singapore, from where they had departed. While it is difficult to reach a definitive conclusion due to the many variables affecting both incidents, it is likely that without lessons learned from United Flight 232, the outcome for the Qantas flight could have been worse. Instead, the aircraft landed safely with no casualties.

However, this does not mean that nothing further could be learned from the Qantas incident. The significant failure triggered more than 80 alerts on the Electronic Centralised Aircraft Monitor (ECAM), taking the plane’s crew over an hour to address, all while airborne with a damaged aircraft. A study by NASA recommended that the Airbus A380 be equipped with a feature allowing multiple alerts to be displayed simultaneously. At the time, the crew could view only one issue at a time, and this improvement would enable the crew to handle multiple alerts more efficiently.