A brief dive into 3D printing in medicine

How can 3D printing revolutionise the way we deal with implants and prosthetics in medicine?

Due to the expiration of many major patents in the last two decades, 3D printing has become widespread. Additionally, an influx in 3D printing related publications means that the topic is a subject of conversation in biotechnology worldwide. In this article I will be discussing the common uses of 3D printing from a surgical perspective as well as various types of 3D printing while considering the issues regarding sterilisation and cost.

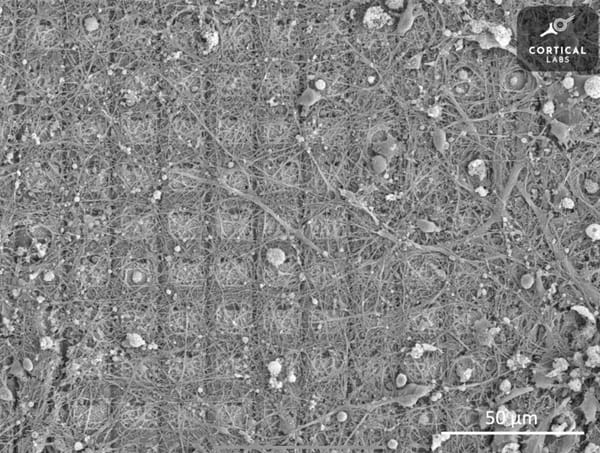

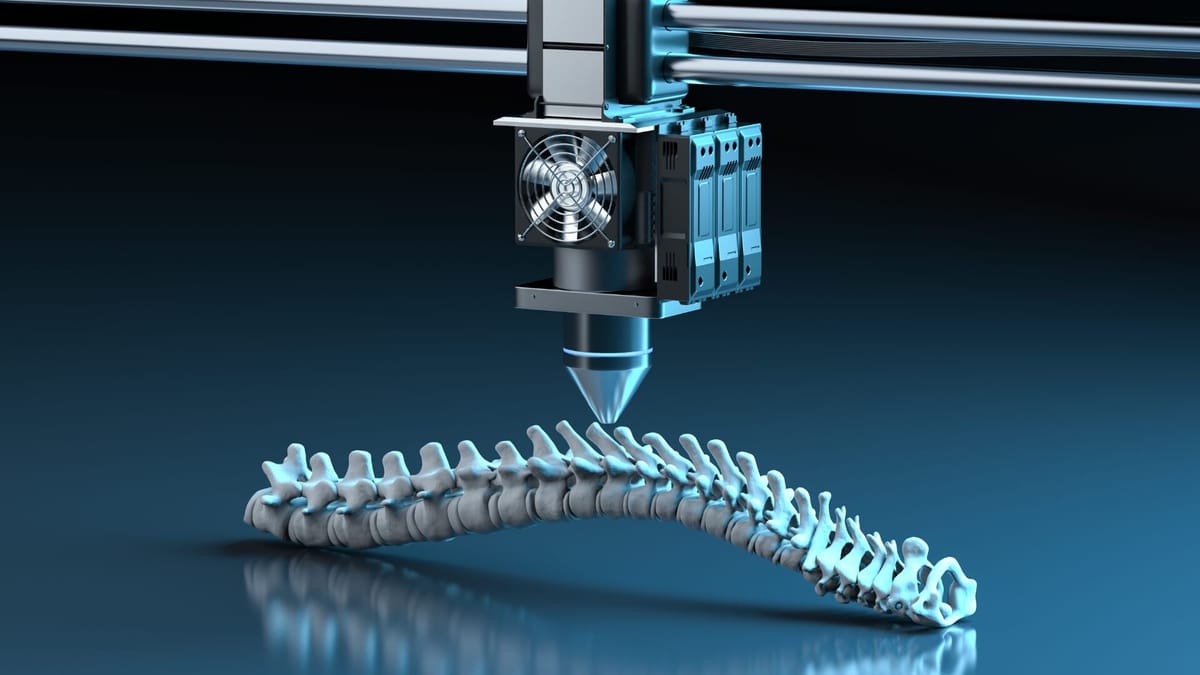

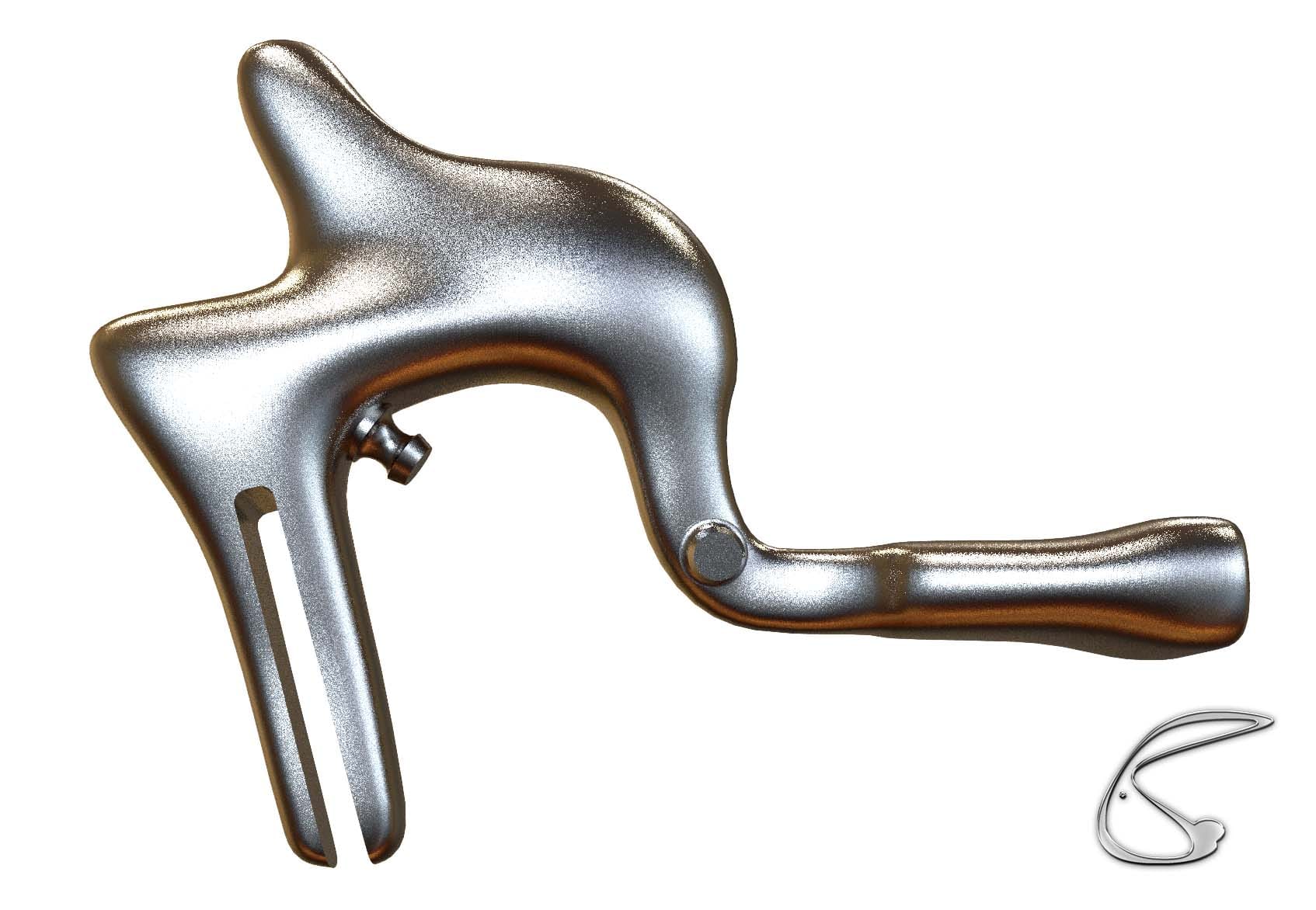

3D Printing over the last decade has been developed to produce a plethora of different items that are commonly utilised in the world of medicine. Examples include: anatomic models, prosthetics, splints, and a wide variety of surgical instruments. 3D printing is especially useful in medicine because the anatomy of each patient is unique, and so implants and instruments can be designed specifically for that person. Another useful way of harnessing 3D printing is by creating implants that have the properties needed to complement the patient's lifestyle. For example, an Olympic swimmer would need an implant that isn't very dense.

The most common bones that are 3D printed are the middle ear bones - the anvil, the hammer, and the stirrup. When a man got into a car accident in South Africa, his doctor had a titanium middle ear implant 3D printed for him after conducting a scan. Titanium was chosen due to its biocompatibility and strength.

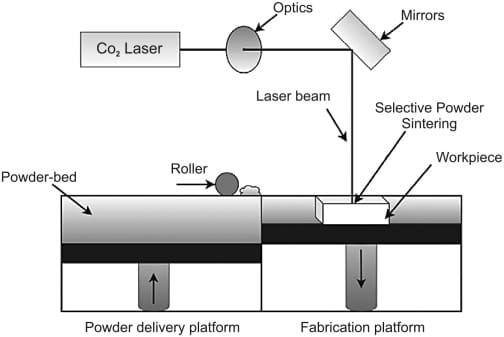

Though titanium was used for the injured man, a more common material used for 3D printing is PLA (polylactic acid) and it is one of the cheapest biocompatible options, ranging from $10 to $100 per kilogram. However, it is not the strongest material, so it is not always the most suitable option from a medical point of view. Sometimes, metals implants are desired and so DMLS (Direct Metal Laser Sintering) 0r SLM (Selective Laser Melting) are used. While both techniques use lasers, DMLS does not actually melt the metal while SLM does. Both options create the implant layer by layer. Depending on the size of the desired implant, the production time could range from an hour to several days. Ceramics are also often used, especially for teeth implants due to its tribological properties and resemblance of a real tooth. In some cases, ceramics are used to print surgical instruments which need high heat resistance - ceramics are suitable as they are heat resistant whilst being strong enough to withstand physical pressure.

The main concern for many people regarding 3D printing is the issue of sterilisation. Of course - surgical implants, instruments, etc. must be sterilised properly in order to prevent infection and cross-contamination. This is especially important for implants as they are stay within the patient for long periods of time. Another reason that sterilisation of surgical instruments is important is that regular sterilisation helps to keep instruments as sharp and effective as possible, prolonging the lifespan of the instruments.

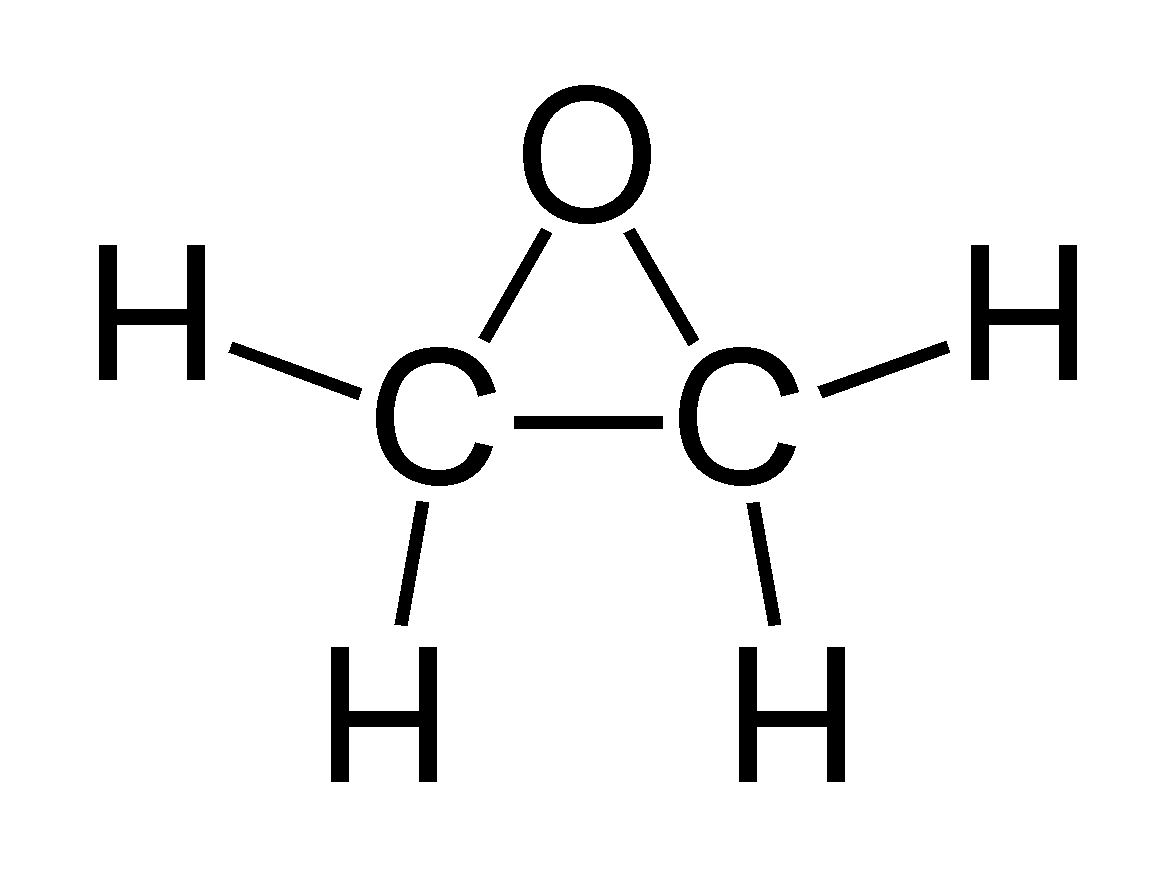

However, as always, medical professionals are way ahead of us. There are many methods of sterilisation, with EtO (ethylene oxide) being the preferred technique, as it is the safest and most highly regulated. Gamma radiation can also be used to sterilise surgical instruments. Despite the prevalence of these options, steam sterilisation is used the most commonly in hospitals as it is cheap, easy to use, and very safe, with temperatures ranging from 120ºC -to 140ºC. The only drawback with this technique is that it may cause damage to products made of certain materials. To prevent this, low-temperature sterilisation is sometimes used as an alternative at a temperature of around 60ºC. The main chemical substance used with this technique is hydrogen peroxide because it produces hydroxyl radicals which attack DNA and other cellular components, hence why it is an extremely efficient high-level disinfectant.

Now, the cost of amateur 3D printers varies massively, from a few hundred pounds to a few thousand, but you can expect professional DMLS and SLM machines to cost between two hundred thousand USD and a million USD. Fortunately, common materials used in 3D printing, like titanium, cost only a dollar a gram. This means that on an industrial scale it might cost as little as $7 for a hospital to print a human femur.

With the number of 3D printing lab facilities increasing from 3 to around 200 in the last 5 years, who knows how the medical world will be transformed by 3D printing in the next decade?